1. Warm up the engine and idle it.

2. Turn the ignition switch off.

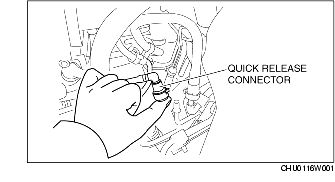

3. Disconnect the quick release connector going to the charcoal canister from the engine room side. (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION.)

4. Start the engine and idle it.

5. After warming up the engine, verify that the vacuum is not present by placing a finger on the quick release connector for approx. 30 s as shown in the figure.

6. Verify that the vacuum is present after approx. 30 s from the engine starting.

1. Warm up the engine and idle it.

2. Turn the ignition switch off.

3. Disconnect the quick release connector going to the charcoal canister from the engine room side. (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION.)

4. Start the engine and idle it.

5. After warming up the engine, verify that the vacuum is not present by placing a finger on the quick release connector for approx. 30 s as shown in the figure.

6. Connect the quick release connector.

7. Connect the WDS or equivalent to the DLC-2.

8. When operating the purge solenoid valve of DUTY 0 % at DUTY 100 % using simulation function EVAPCP, verify that the engine idles roughly or stops.

1. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION.)

2. Remove the extension manifold. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

3. Remove the purge solenoid valve.

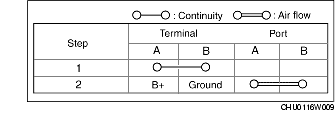

4. Inspect air flow between the ports under the following conditions: