PROPELLER SHAFT INSPECTION

BHE031525002W06

For Carbon-Fiber Propeller Shaft

-

Caution

-

• Replace the propeller shaft if it is dropped.

-

• Handle the propeller shaft with care so that the pipe is not damaged from striking surrounding objects or other impacts.

-

• Replace the propeller shaft if there is any chipping or warping of the pipe.

-

• Protect the propeller shaft from damage and handle with careful attention when working.

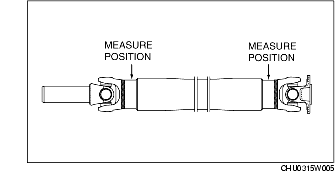

1. Use a dial gauge to measure the runout of the propeller shaft at each position.

-

• If it exceeds the maximum specification, replace the propeller shaft.

-

Maximum runout

-

0.4 mm {0.016 in}

2. Inspect the play and rotation of the joint by turning the universal joint in the directions shown by the arrows.

-

Initial torque (Reference value)

-

0.29-0.98 N·m

-

{3.0-10 kgf·cm, 2.7-8.6 in·lbf}

-

• If there is any play or excessive initial torque, replace the propeller shaft.

3. Verify that the propeller shaft has no bends or damage.

-

• If there is any malfunction, replace the propeller shaft.

4. Verify that there is a gap between the pipe and yoke flange.

-

• If there is any malfunction, replace the propeller shaft.

5. Verify that there is no cracking, peeling or similar damage to the seal (where the pipe and yoke connect).

-

• If there is any malfunction, replace the propeller shaft.

For Steel Propeller Shaft

1. Use a dial gauge to measure the runout of the propeller shaft at each position.

-

• If it exceeds the maximum specification, replace the propeller shaft.

-

Maximum runout

-

0.4 mm {0.016 in}

2. Inspect the play and rotation of the joint by turning the universal joint in the direction shown by the arrow.

-

Initial torque (Reference value)

-

0.29-0.98 N·m

-

{3.0-10 kgf·cm, 2.7-8.6 in·lbf}

-

• If there is excessive play or initial torque, replace the propeller shaft.