SECONDARY AIR INJECTION (AIR) PUMP INSPECTION

BHE011613988W06

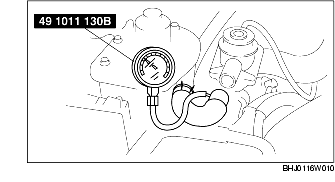

Discharging Pressure Inspection

Without using WDS or equivalent

1. Remove the air hose between the AIR pump and AIR control valve at the AIR control valve side.

2. Install the SST on the AIR control side using tape to prevent air leakage.

3. Position the PCM out of the way with the connectors still connected. (See PCM REMOVAL/INSTALLATION.)

4. Start the engine, turn all electrical loads off, and idle the engine after completely warming it up.

5. Connect the AIR pump relay terminal A to the ground, and operate the AIR pump.

-

Caution

-

• When connecting the secondary air injection pump relay to the body ground, short the specified terminal, because shorting the wrong terminal may cause malfunctions.

-

• Do not operate the secondary air injection pump for more than 1 min to avoid damaging the pump.

-

• Stop the engine and wait for 1 h or more after energization of the secondary air injection pump to allow it to cool down before operating it again.

6. Verify that the discharging pressure of the AIR pump is within the specification.

-

• If not within the specification of the discharge pressure, inspect the following:

-

– PCM terminal 4O voltage

-

– AIR pump relay

-

• If it is within the specification, inspect continuity for the AIR pump.

-

Discharging pressure

-

13.7 kPa {0.14 kgf/cm2, 1.99 psi} or more

Using WDS or equivalent

1. Remove the air hose between the AIR pump and AIR control valve at the AIR control valve side.

2. Install the SST on the AIR control side using tape to prevent air leakage.

3. Start the engine, turn all electrical loads off, and idle the engine after completely warming it up.

4. Connect the WDS or equivalent to the DLC-2.

5. Turn the PID AIP RLY from off to on position using the simulation function.

-

Caution

-

• When connecting the secondary air injection pump relay to the body ground, short the specified terminal, because shorting the wrong terminal may cause malfunctions.

-

• Do not operate the secondary air injection pump for more than 1 min to avoid damaging the pump.

-

• Stop the engine and wait for 1 h or more after energization of the secondary air injection pump to allow it to cool down before operating it again.

6. Verify that the discharging pressure of the AIR pump is within the specification.

-

• If not within the specification, inspect the following:

-

– PCM terminal 4O voltage

-

– AIR pump relay

-

• If it is within the specification, inspect the continuity for the AIR pump.

-

Discharging pressure

-

13.7 kPa {0.14 kgf/cm2, 1.99 psi} or more

Continuity Inspection

1. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION.)

2. Disconnect the AIR pump connector.

3. Inspect for continuity between the AIR pump terminals A and B.

-

• If there is continuity, inspect the related wiring harnesses.

-

• If there is no continuity, replace the AIR pump. (See SECONDARY AIR INJECTION (AIR) PUMP REMOVAL/INSTALLATION.)